allTrac app for iPhone and iPad

Developer: Nessis

First release : 28 Sep 2016

App size: 22.07 Mb

Managing workflow is excessively, and needlessly, complicated. Proper scheduling and delegation is the crossroads between art and science. This is why manufacturing companies are constantly focusing on continuous improvement in order to find ways to save time and money. The question that burns at the heart of continuous improvement is: How can your business be run simpler?

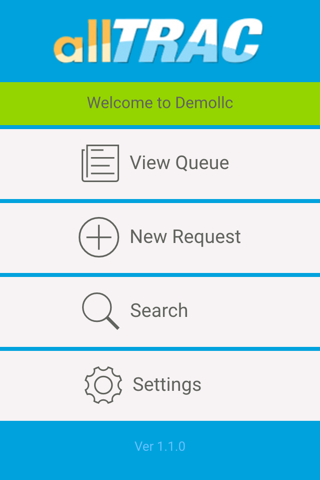

Here at Nessis Inc., we are from the manufacturing industry and we have built software to solve your problems. Problems with Project Management, Business Management, and Business Development are commonplace. This is why we built allTrac a comprehensive issue tracking system that can manage projects.

But allTrac does more than just modernize management; it empowers all aspects of a business to submit suggestions and creates a forum for continuous improvement. Fostering a collaborative work environment where visions can be shared and innovation can be implemented is an evolution in how businesses operate. Self-reflection and employee contributions directly lead to a more efficient and engaged workforce.

Total quality management and statistical quality control are the future of manufacturing. For huge growth you do not need to reinvent yourself, you just need to keep doing what you are good at, while we reduce waste, noncompliance, and optimize training. If you have discovered programs like Six Sigma, Kaizen, and Toyota Way, then the next step is to actualize these improvements. We are just here to help.